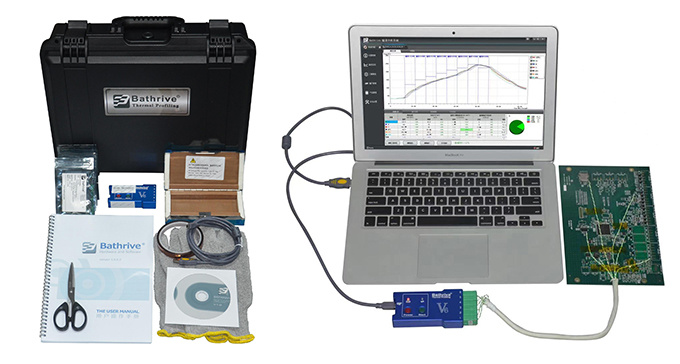

Product model: V6 Number of channels: 6 channels

Product brand: Bathrive Chinese name: Brad

Product use: professional test SMT wave soldering. Reflow soldering temperature and drawing temperature curve, furnace temperature analysis and output analysis report, providing an effective basis for furnace parameter setting and product quality control.

Application area: SMT manufacturing, etc

Product Features:

- Small and powerful, designed for more than 10 years of service life

- With high measurement accuracy of +/-0.5°C and fast speed, up to 0.1 seconds/time, it can easily meet the challenges of any field of temperature measurement

- High-speed USB interface communication and charging are integrated, eliminating the need for additional charging forever

- The 3 trigger start/stop methods can be optimized at will to achieve intelligent start and stop without manual intervention

- 1000MA polymer rechargeable battery powered

- Compare and analyze up to 100 sets of curve overlaps

- Complete firmware information prompts, users can view the use records and hardware configuration information of the instrument at any time

- Intelligent PWI index analysis, with a single index to visually understand whether curve analysis results are qualified or not

- The instrument time can be set or calibrated to synchronize with a computer or set to a specified time

- Powerful curve editing features to modify, move, align, cut, and more

- Curve tolerance band display and discrimination

- Highlight analysis segments to visually map analysis data to curved segments

- Export, import, and modify curve data

- Independent process analysis can be used for each thermocouple or the same process analysis can be used for all thermocouples

- Temperature cursor custom analysis, horizontal temperature line, vertical time line, and intercept temperature data analysis for any time period

Product Specifications:

1 | Instrument model | V6 |

2 | Instrument size | 20*53*100 mm(H*W*L) |

3 | Measurement accuracy | +/-0.5℃ |

4 | Temperature resolution | 0.1℃ |

5 | Sampling frequency | 0.1 seconds/time ~ once per hour |

6 | Storage space | 4M |

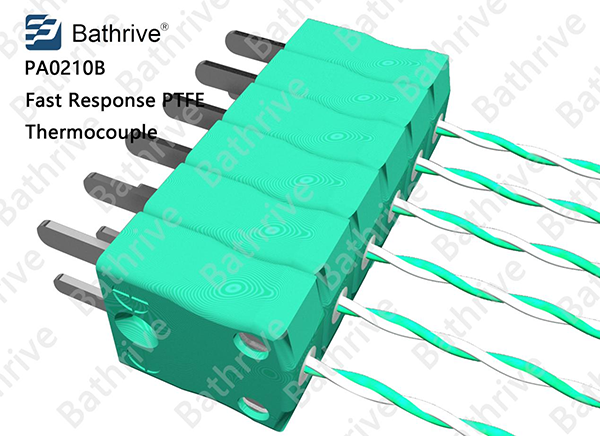

7 | Number of channels | 6 |

8 | Number of storage groups | 16 |

9 | Battery capacity | 1000MA |

10 | Startup mode | Key trigger, temperature trigger, delay trigger |

11 | Stop mode | Key trigger, temperature trigger, delay trigger |

12 | Instrument operating temperature | -40~+85℃ |

13 | Temperature measurement range | 0~+500℃ |

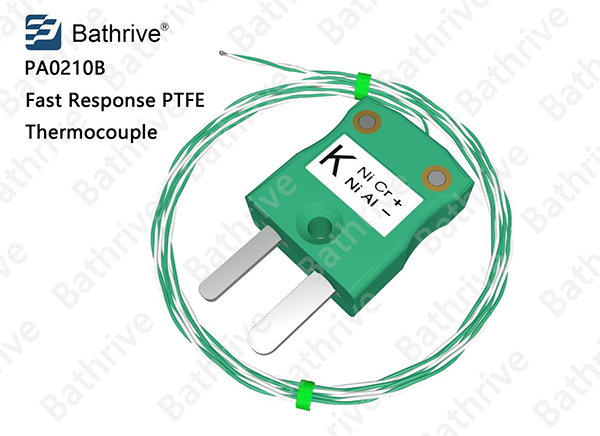

14 | Thermocouple type | Type K |

Software function introduction:

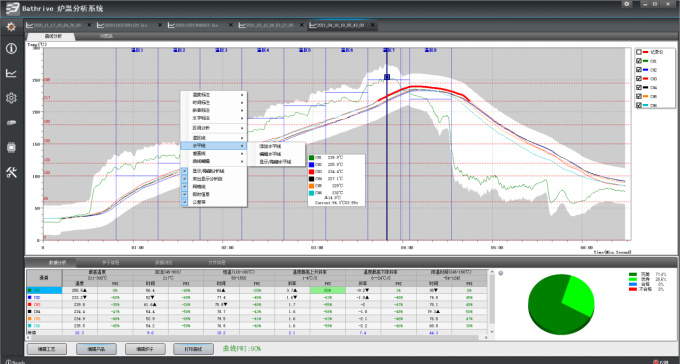

1: Reflow curve analysis chart, you can set the name, color, thickness of each curve at will, adjust the order of the data analysis list at will, and close or open each data analysis project at will by dragging the mouse, without re-entering the process data.

2: Intuitive curve tolerance band comparison display, tolerance band tolerance range can be set, out-of-tolerance band curve will automatically turn red, highlight the analysis section, the curve section corresponding to the analysis item is bolded and highlighted, so that the data analysis becomes more intuitive, real-time information is convenient to view the temperature and time information of the curve at any time.

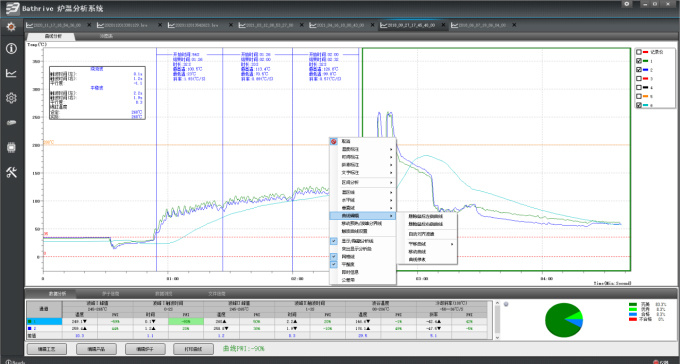

3: Wave soldering curve analysis diagram: can automatically calculate the peak, contact time, parallelism, chain speed, tin furnace temperature, addable interval analysis, etc.

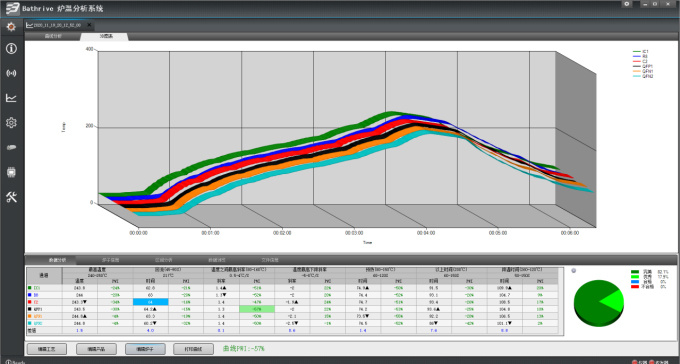

4 : 3D Graph : The 3D graph can be rotated so that you can visually see the details of the temperature curve changes.

5: Curve browsing, including historical curves that have been downloaded to the PC end. If the instrument is connected to the computer, it can also view the temperature curves that have been tested inside the instrument. The instrument itself can save up to 16 production line data, with each data lasting up to 15 minutes. The historical curve name, download time, testing time, etc. can be modified, and deletion, batch deletion, copying, curve overlap analysis, importing data, etc. can also be completed.

6. Process editing interface: you can specify an independent process for each curve, you can also let all thermocouples use the same process, which is especially important when the volume of components is different, the analysis items that can be added include: the highest slope between temperatures, the highest slope of temperature rise, the highest slope of temperature drop, preheating, constant temperature, above time, reflow, maximum temperature, cooling time, average cooling slope, etc., and each analysis option can be added countless times, for example: you can add constant temperature 1, constant temperature 2, constant temperature 3... The title of the analysis option can also be renamed according to your needs.

7: Rich curve analysis methods: including adding temperature annotation, time annotation, any temperature point time annotation, slope annotation, interval analysis, adding horizontal temperature lines, adding vertical time axis, curve alignment, curve movement, curve shearing, curve trimming, temperature zone line display and adjustment, showing/hiding analysis lines, curve zooming and moving, channel curve display/closing and color line width adjustment, pie chart can more intuitively display the status of data analysis results, You can also add or delete pie chart list analysis items.

8: Perfect curve analysis report: including temperature curve, analysis line, temperature zone information, product name, furnace name, temperature zone temperature, chain speed, process name and detailed information list, test plate name, test board use times, instrument number, sampling frequency, solder paste information, product pictures, operation and confirmation project signature, add remarks, etc. Both row width and column height can be adjusted and automatically adapted, ensuring that a single page of A4 paper can be displayed to the maximum extent of the analysis report, thus avoiding paper waste.

9:Hot box

Adopting aviation level heat isolation technology, the insulation time is maximized under certain temperature and space conditions, and different specifications of insulation boxes are equipped according to different usage scenarios

model:FBT1608

Size specification: 164 * 82* 36 (mm)

Heat resistance time: 150 ℃ 200 ℃ 250 ℃ 300 ℃

26minutes 17minutes 11minutes 8minutes

10:Thermocouple assembly

Corresponding thermocouple components can be equipped according to different usage scenarios

Product standard parts:

1 | V6 thermometer host | 1 unit |

2 | High temperature heat insulation box | 1 unit |

3 | Thermocouple assembly | 6 sets |

4 | High-temperature gloves | 1 pair |

5 | High temperature tape | 1 volume |

6 | Software CD | 1 sheet |

7 | USB data download cable | 1 article |

8 | Software operation manual | 1 copy |

9 | Factory inspection report | 1 serving |

10 | Industrial scissors | 1 handful |

The full range of Bathrive brand products provide 2 years or 24 months free maintenance service, free software upgrade for life, Bathrive Software or hardware upgrades or improvements to the full range of products will not be notified separately, for more detailed product information, please check the Bathrive brand official website www.bathrive.com, / Or / Email:bathrive@163.com

24-hour service hotline: 400-889-3896

Not enoughThanks for watching!!

Phone

Phone